热门供应商

该产品暂无相关的供应商

PK的排行更多

- 台湾路昌 振动...

- 日本理音 测振仪...

- 日本理音 激...

- 美国康塔仪器 ...

- 北京拓必拓 微...

- 上海舜宇恒平 在...

- 荷兰Skalar...

- 德国德尔格 ...

- 北京拓必拓 超...

- 日本Kanoma...

最新更新的同类仪器更多

最新产品 > 样品处理设备 > 混合分散设备 > 均质机>Art 吸粉式分散均质机 collovelox/...

更新时间:2025-01-23 00:43:46 点击:6922次

| 产品型号 | collovelox/EML/Muti-homo |

|---|---|

| 参考报价 | 返回顶部 面议 |

| 基本规格 | |

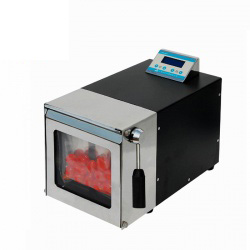

| 产品类型 | 返回顶部 均质机 |

| 品牌 | 返回顶部 德国ART |

| 产地 | 返回顶部 德国 |

| 返回顶部 我来纠错(有奖) | |

| 技术参数 | |

| 均质速度 | 返回顶部 from 340 l/h up to 32.000 l/h(related to water). |

| 其他信息 | |

| 产品简介 |

仪器简介:

Function principle

Further requirements to be taken into account include:

An additional speciality is the variable gap adjustment between rotor and stator to the needs of the product. Adjustment of the gap can be accomplished while the mill is in use. A special pumping wheel, fixed to the rotor is responsible for the feeding of the product. Over a powder sucking system (optional) it is possible to create vacuum and to suck powder or liquid directly into the mixing area.

The special advantage of a COLLOVELOX colloidal mill is its flexibility. |

| 应用文章 | 返回顶部 此仪器尚未有相关文章 |

| 产品样本 | 此仪器尚未有相关样本 返回顶部 |

| 应用范围 | 返回顶部此仪器尚未有相关应用 |

| 用户数 | 返回顶部 此仪器尚未有用户数 |

| 技术创新 | EML Function principle Sucking of powder and/or liquid into a receiver liquid. The powder suction system. EML is working according the ?Venturi-Principle“. After a speed up of a receiver liquid with a pump through the injector nozzle, a vacuum will be created inside of the mixing chamber. The injector nozzle can be changed easily by hand to fit the different powder types and/or powder amount. Because of the generated vacuum in the chamber the powder and/or liquid will be sucked onto the top of the jet stream particle by particle, moistened therefore and carried away by the jet stream immediately. Based on this special system the air in the powder is swimming with big bubbles on the surface of the liquid stream and can easily disappear after the entrance in a tank. Advantage of the system: no air in the product and less of foam on the top. The special advantage of the system EML is its flexibility. The system can be adapted to the existing infrastructure of the customer’s facility and its specific needs: fix installation / moveable; adjustment to existing product viscosities; inline/recirculation system, powder dosing over a hopper / suction pipe / Big-Bag; dosing by hand/ over an automatic dosing system. The powder injection system EML is suitable for capacities from 0 up to 70 kg/min 返回顶部 |

| 最新动态 | 返回顶部 此仪器尚未有最新动态 |

| 相关视频 | 返回顶部 此仪器尚未有相关视频 |

| 相关耗材和配件 | 此仪器尚未有相关耗材和配件 返回顶部 |

| 相关仪器 | 返回顶部 此仪器尚未有相关仪器 |

| 网友评分 |

5星:0人 4星:0人 3星:0人 2星:0人 1星:0人 返回顶部 |

|

该产品暂无相关的供应商 |

- 网友评论:

- 已有0条评论

搜索

搜索